Research

The real background and peak asymmetry in diffraction on nanocrystalline metals.

The publication by by Zbigniew Kaszkur, Maciej Zieliński, Wojciech Juszczyk J. Appl. Cryst. (2017). 50, 585-593.

The paper deals with two fundamental problems in powder diffraction on nanocrystalline solids- finding the real background of a diffraction peak and the peak asymmetry.

The 'background problem' is at the basis of PXRD analysis. All material estimates deeply depend on it. If microstrain plays no important role in the diffraction pattern, the proposed analysis is the objective approach.

The paper explains why the diffraction peaks from nanometals are usually asymmetric and how one can extract from the peak shape the lattice constant - size dependency and the column size distribution. The asymmetry arises from a common phenomenon for nanocrystalline solids- size dependency of the measured lattice constant. For nanocrystalline metals this can be modified by adsorption from a gas atmosphere.

A fundamental problem in interpretation of diffraction from a multi-phase material is to separate peaks originating from only one phase from the background intensity. To this end our Team made a spectacular step - we have developed method to calculate the 'true background' of the peak, based on exact physical criteria. We proposed fitting the peaks to the Voigt shape function and application of condition given by Balzar (Balzar, D. (1993). J. Res. Natl Inst. Stand. Technol. 98, 321–353). The Voigt function as a convolution of Cauchy and Gauss functions is a particularly suitable expression for the peak shape owing to its simple Fourier properties. They enable simple, direct calculation of atom Column Length Distribution (CLD). Using the above mentioned criterion one can optimize the fit in respect to the background parameters.

The method is applicable if so called microstrains are not important factors in the peak broadening - the situation often met in catalytic studies. Currently the method was tested on supported metal nanocrystals.

The developed method enables in depth insight into the structure of nanocrystals and their surface. Monitoring the structural evolution during physico-chemical process- e.g. catalytic reaction at the surface of metal catalyst, may provide evidence of reversible elongations of nanocrystals along some directions. They result from a stronger bonding of some crystal faces with the adsorbing reagents. The crystallite responds by increasing surface of that faces, changing its shape and minimizing the energy. Such changes we have observed e.g. for nanocrystalline gold.

The proposed approach is especially 'strong' when applied to pattern evolution during in situ treatment of metal nanocrystals.

The developed method paves the way to understand why nanocrystalline gold makes a good catalyst in oxidation of carbon monoxide - the principal poison in the fuel cell technology.

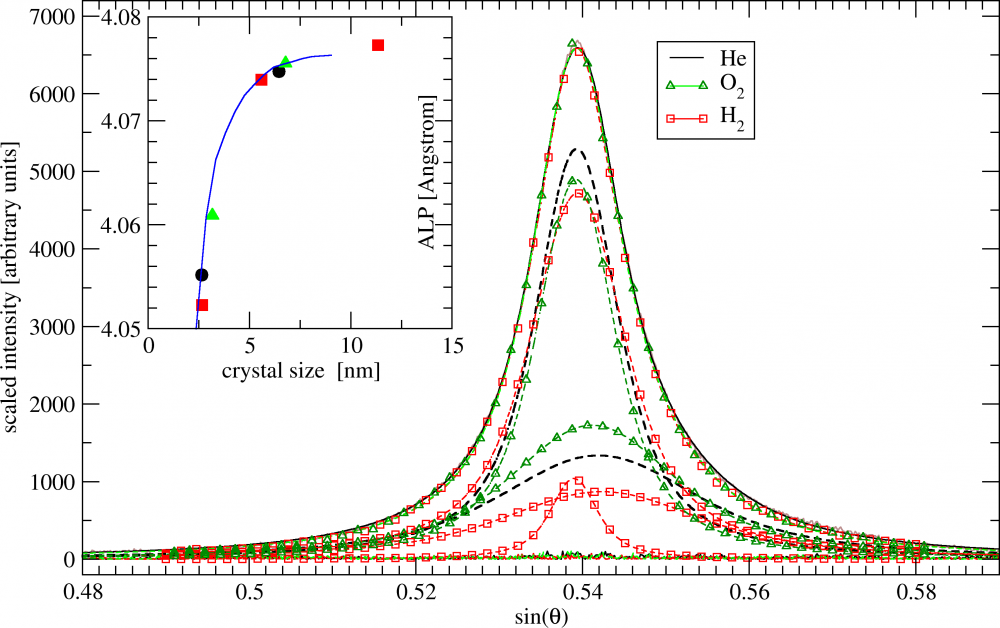

Peak shape of 220 reflection of the Au/C sample in H2 - red line, He - black line and O2 - green line and its Voigt function fit. Inset - the ALP (apparent lattice parameter) values for the constituent Voigt profiles versus crystal size estimated from Scherrer formula.

Note that the extracted lattice parameter vs. size dependency (inset) lays on a smooth curve coinciding with theoretically predicted for gold effect of the surface relaxation alone. Shifts along this curve with changing the gas atmosphere confirm changing the size along [220] direction.